Robot Controller

The robot controller component implements a general robot controller, capable of executing a variety of instructions. The robot controller automatically computes the forward and inverse kinematics and can seamlessly handle closed kinematic structures. Every type of industrial robot is supported. The axes that make up the robot are automatically detected by the robot controller. Please see the API documentation if you would like to learn more about how to create scripted programs.

If the robot contains joints for a tool (such as a mechanical gripper), you can manually specify the axes to be solved through the joints property of the component, which allows you to exclude the joints for the end effector so that they aren’t solved by the robot controller when computing the inverse kinematics.

Properties

The robot controller component properties that are accessible through the inspector.

TCP

The entity that serves as the Tool Center Point (TCP) for the robot. This entity must be a child of the robot. The Robot TCP component may be used to accurately position the TCP by selecting a feature from the mesh. If the entity contains a Robot TCP component, then this component will be used to determine the position and orientation of the TCP. If the entity doesn’t contain a Robot TCP Component, then the transform of the TCP entity will be used to determine the pose instead.

Programs

The list of robot programs. A robot controller can have multiple programs. Each program must have a case-insentitive unique name. If the program is called Main, then this program will be executed automatically. Programs contain an ordered list of instructions that get executed. The following instruction types are available:

- Empty: An empty (placeholder) instruction that performs no action.

- Pause: Instructs the controller to pause execution of the program for a set number of seconds.

- Linear Move: Instructs the controller to perform a linear move (MoveL, LIN) to the specified target entity.

- Joint Move: Instructs the controller to perform a joint move (MoveJ, PTP) to the specified target entity.

- Path Move: Instructs the controller to perform a path move (MoveP).

- Set Speed: Instructs the controller to change zero or more motion parameters.

- Set TCP: Instructs the controller to change the currently active TCP to the specified entity.

- Await Signal: Instructs the controller to pause execution until the specified signal reports a particular value.

- Set Signal: Instructs the controller to set the specified signal to a particular value.

- Call: Instructs the controller to call the specified program.

- Conditional Call: Instructs the controller to call the specified program if the specified signal reports a particular value.

- Call Script: Instructs the controller to call the specified scripted program.

Joints

The optional list of joints to be controlled by the robot controller. If no joints are specified, then the robot controller will automatically detect all the joints on any descendant entities. If the robot contains a jointed tool (such as a mechanical gripper), then it is necessary to provide the list of joints that should be controlled. This ensures that the robot controller will not attempt to control the joints belonging to the tool.

Linear Speed

The maximum/target linear speed for the TCP that the robot controller tries to achieve when performing linear moves.

Linear Acceleration

The linear acceleration/deceleration for the TCP that the robot controller should use when performing linear moves.

Angular Speed

The maximum/target rotational speed for the TCP that the robot controller tries to achieve when performing linear moves.

Angular Acceleration

The rotational acceleration/deceleration for the TCP that the robot controller should use when performing linear moves.

Joint Speed

The multiplier to apply to the target speed of all joint motors when performing joint moves. For example, a multiplier of 2.0 (200%) will allow the motors to move up to twice as fast as the initial target speeds set on the motors.

Joint Acceleration

The multiplier to apply to the acceleration/deceleration of all joint motors when performing joint moves. For example, a multiplier of 0.5 (50%) will cause the motors to accelerate/decelerate half as fast as the initial acceleration/deceleration set on the motors.

Instructions

The robot controller supports a wide range of instructions that can be executed.

Empty

The empty instruction is used as a placeholder. It performs no action when executed.

Pause

The pause instruction causes the robot controller to pause execution for a fixed number of seconds.

Linear Move

The linear move (MoveL, LIN) instruction commands the robot controller to perform a linear movement towards the specified target entity. The TCP will be moved along a line from its current pose to the target pose. Note that linear moves may encounter singularities. The speed at which the TCP moves through world space is governed by the Linear Speed and Linear Acceleration properties. The rotational speed of the TCP is governed by the Angular Speed and Angular Acceleration properties. The initial target speeds and accelerations set on the motors are ignored.

Joint Move

The joint move (MoveJ, PTP) instruction commands the robot controller to perform a joint movement to the specified target entity. The path that the TCP takes is somewhat unpredictable, though still deterministic. The inverse kinematics for the robot are solved, then the joints are commanded to move to the positions that were solved. The speed which the joints move is determined such that all joints arrive at their target positions at the same time, whilst ensuring not to violate any speeds/accelerations set on the motors. However, keep in mind that the Joint Speed and Joint Acceleration multipliers get applied, which may be used to adjust the maximum speed and acceleration of the motors.

It is possible to select a joint move robot solution through the UI, which solves the inverse kinematics at design time, instead of when the joint move instruction is executed. A preview of the robot being solved to the target pose will be shown as you hover over the solution in the dialog window. This can be used to improve runtime performance and ensures that the path followed by the TCP is more predictable/controllable.

Path Move

The path move (MoveP) instruction commands the robot controller to move along a path. The path that the TCP takes is specifed by selecting a curve using the feature selection tool. The curve will be automatically detected as either a line, polyline, circle, arc or a composite curve that consists of lines and arcs. The path move will discretize the curve according to the discretization parameter specified. The discretization parameter controls the number of points in the discretized curve. You can specify both the start point and length of the path as a percentage. The default value for the start is 0% and for the length is 100%.

The rotation of the TCP along the path can be one of two modes:

- Constant: Orientation is constant along the path.

- Follow Curve: Orientation follows the path.

The global rotation offset can be used to offset the rotation of the frames along the path, for all points in the discretized curve. The local rotation offsets can be used to offset the rotation of the frames along the path for specific points at a specified percentage along the path. The frames of the points between two local rotation offsets (e.g. local rotation at 20% and local rotation at 30%) are then spherically interpolated. If a point does not exist at the specified percentage in the discretized curve, a new point will be inserted at that position with the specified local rotation.

Set Speed

The set speed instruction can be used to modify the motion parameters of the robot controller during the execution of a program. The Enable property specifies which motion parameters should be modified. Note that multiple parameters may be modified by a single set speed instruction. This instruction is used to adjust the speed/acceleration of the robot for a particular sequence of moves.

Set TCP

The set tool center point instruction can be used to modify the active tool center point of the robot controller during the execution of a program. This is generally used to switch between multiple end effectors. For example, the instruction could be used to switch between two different suction cups. The TCP entity selected must be a descendant of the entity to which the robot controller is attached.

Await Signal

The await signal instruction is used to pause execution of the program until a specified signal on the robot controller’s IO reports a particular value. For example, this instruction can be used to pause execution until a sensor has been blocked. Note that you must first create a signal/variable on the robot controller’s IO.

Set Signal

The set signal instruction is used to set the value of a signal on the robot controller’s IO. For example, this instruction can be used to toggle the state of a suction gripper. Note that you must first create a signal/variable on the robot controller’s IO.

Call

The call instruction is used to instruct the robot controller to execute another program. This should be used to group related instructions into a separate program that can be called from the main program. For example, a program to pick and place an object can be called from the main program.

Conditional Call

The conditional call instruction is used to instruct the robot controller to execute another program if and only if a specified signal reports a particular value. This is used for branching (if statement) control. Note that you must first create a signal/variable on the robot controller’s IO.

Call Script

The call script instruction can be used to instruct the robot controller to execute a scripted program. Scripted programs should be used for advanced tasks, such as picking moving parts off a conveyor belt. For example, the moveLinearToIntercept() function that instructs the controller to perform a linear move to intercept the moving entity, cannot be called directly from the inspector UI, but can be called by a scripted robot program.

Creating a scripted robot program involves creating a scripted component that inherits from the RobotProgramComponent class. An example is provided below:

import { type RobotControllerComponent, RobotProgramComponent, SensorComponent, Entity, Future, Sequence, Handle } from "prototwin";

import { Frame, Quat, Vec3, Wait, Units, UnitType } from "prototwin";

export class MyScriptedProgram extends RobotProgramComponent {

@Units(UnitType.Time)

public pauseDuration: number = 0.5;

public sensor: Handle<SensorComponent> = this.handle(SensorComponent);

public target: Handle<Entity> = this.handle(Entity);

constructor(entity: Entity) {

super(entity);

}

public execute(controller: RobotControllerComponent): Future<void> {

const sequence = new Sequence(false);

sequence.add(() => controller.moveJoint(new Frame(Quat.identity, new Vec3(-0.2, 0, 0.2))));

sequence.add(() => Wait.seconds(this.pauseDuration));

sequence.add(() => controller.moveJoint(new Frame(Quat.identity, new Vec3(-0.2, 0, -0.2))));

sequence.add(() => Wait.value(this.sensor.value!.io.state, true));

sequence.add(() => controller.moveLinearToIntercept(this.target.value!, Frame.translation(new Vec3(0, 0.05, 0))));

return sequence.run();

}

}To call a scripted program, you must first add the scripted component to an entity. The scripted program will then be selectable under the Script property of the call script instruction.

Please see the relevant API documentation that may be helpful when creating scripted robot programs:

- Robot Controller Component

- Robot Program Component

- Robot Program

- Handle

- Sequence

- Future

- Wait

- Frame

- Quat

- Vec3

It is also worth noting that you can use ProtoTwin’s AI assistant Torq to create scripted robot programs from natural language, instead of using the GUI or writing the code from scratch.

IO

The IO signals for the robot controller component. Please see the RobotControllerIO API documentation for more details.

Error

A uint32 readable (output) signal that stores the error code. A non-zero value indicates that an error has occurred. The error codes are provided below:

- 0: No Errors.

- 1: Failed to complete a joint move.

- 2: Failed to complete a linear move.

- 4: Failed to complete a path move.

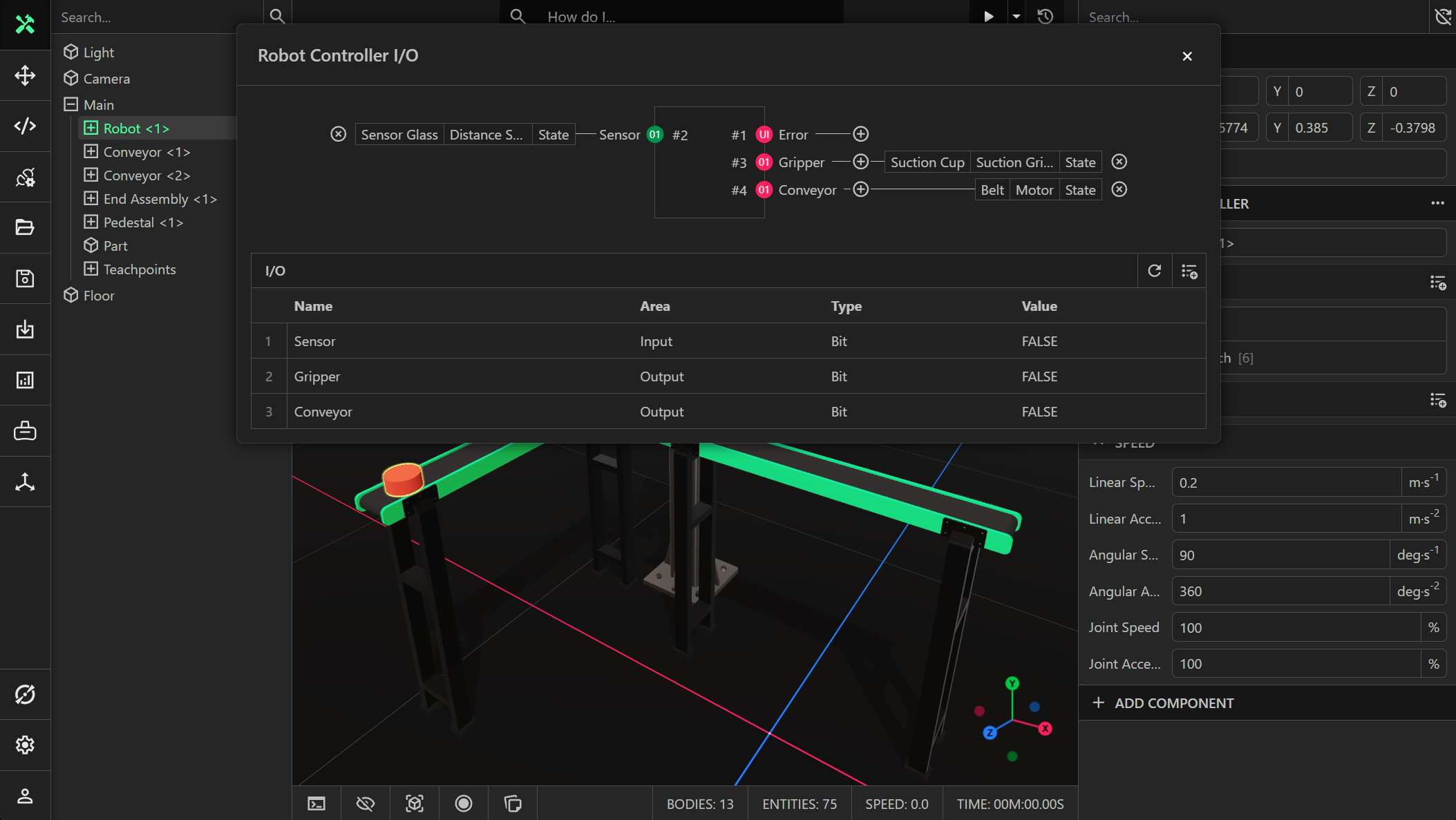

Configurable IO

The robot controller component has its own configurable IO, that allows users to add or remove IO points at design time. You can create a variable with a specified name, area (input/output), data type and value. You can then use direct connections to bind these signals to other signals, defined by a Entity/Component/Property path.

For example, in the screenshot above an input signal called Sensor and two output signals called Gripper and Conveyor were created. A direct IO connection was created between the Sensor signal and the state of the distance sensor component, so that the robot controller knows when the sensor is blocked. Another direct IO connection between the Gripper signal and the suction gripper component on the suction cup entity of the robot was created, which allows the robot to pick up the object. Finally, a direct IO connection between the Conveyor signal and the state of the motor for the conveyor belt entity was created. This allows the robot to turn the conveyor belt on/off.