Siemens PLC Connectivity

ProtoTwin Connect supports the Siemens S7 protocol for connection to S7-1200, S7-1500 and LOGO! PLCs.

Connect to Siemens S7-1200/1500

TIA Portal Project Setup

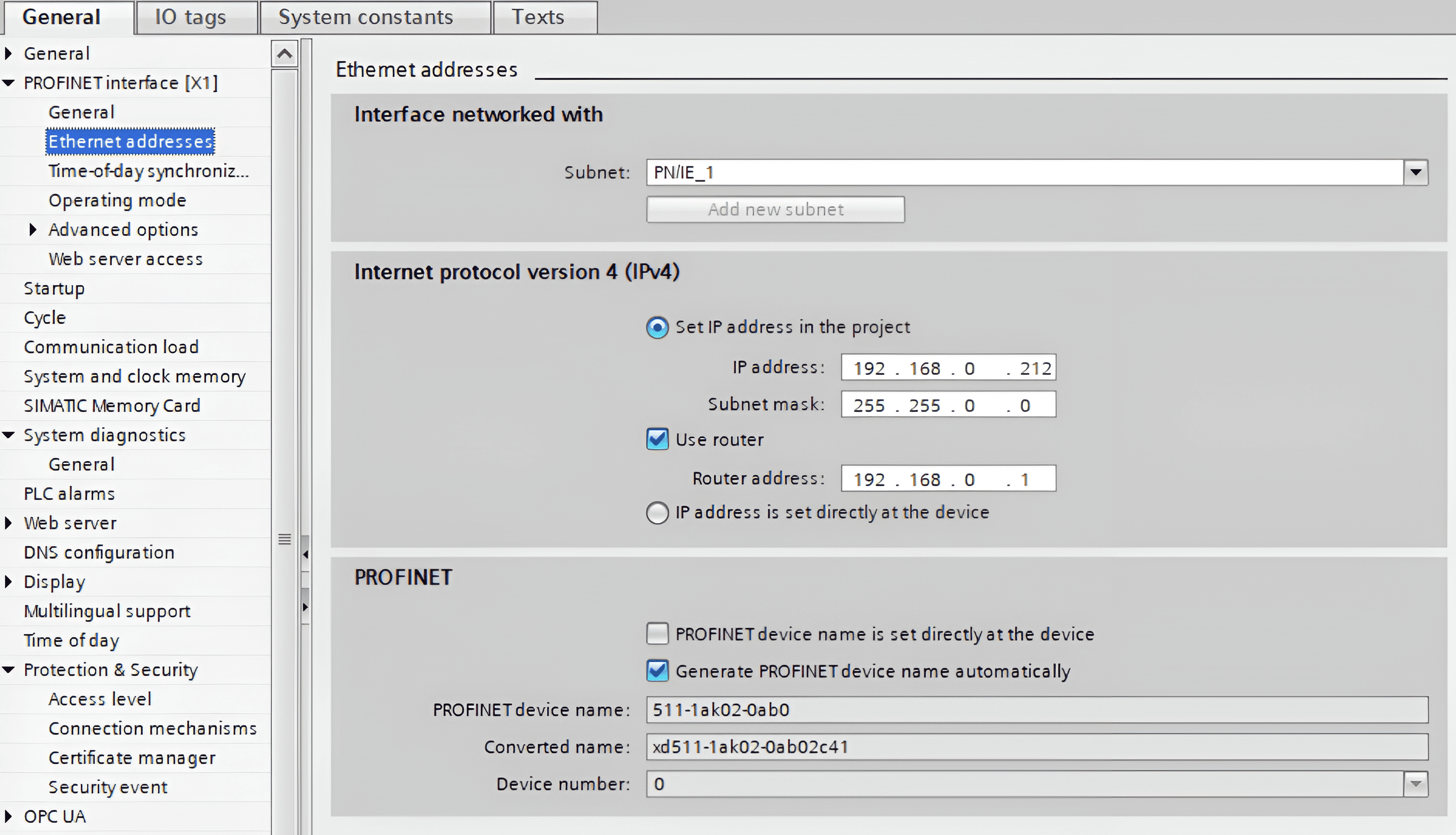

You must configure the TIA Portal project to allow S7 connections to the PLC. Firstly, under Device Configuration / PROFINET Interface, ensure that you have assigned a static IP address to the PLC. You’ll need to enter this IP address when configuring the server in ProtoTwin Connect.

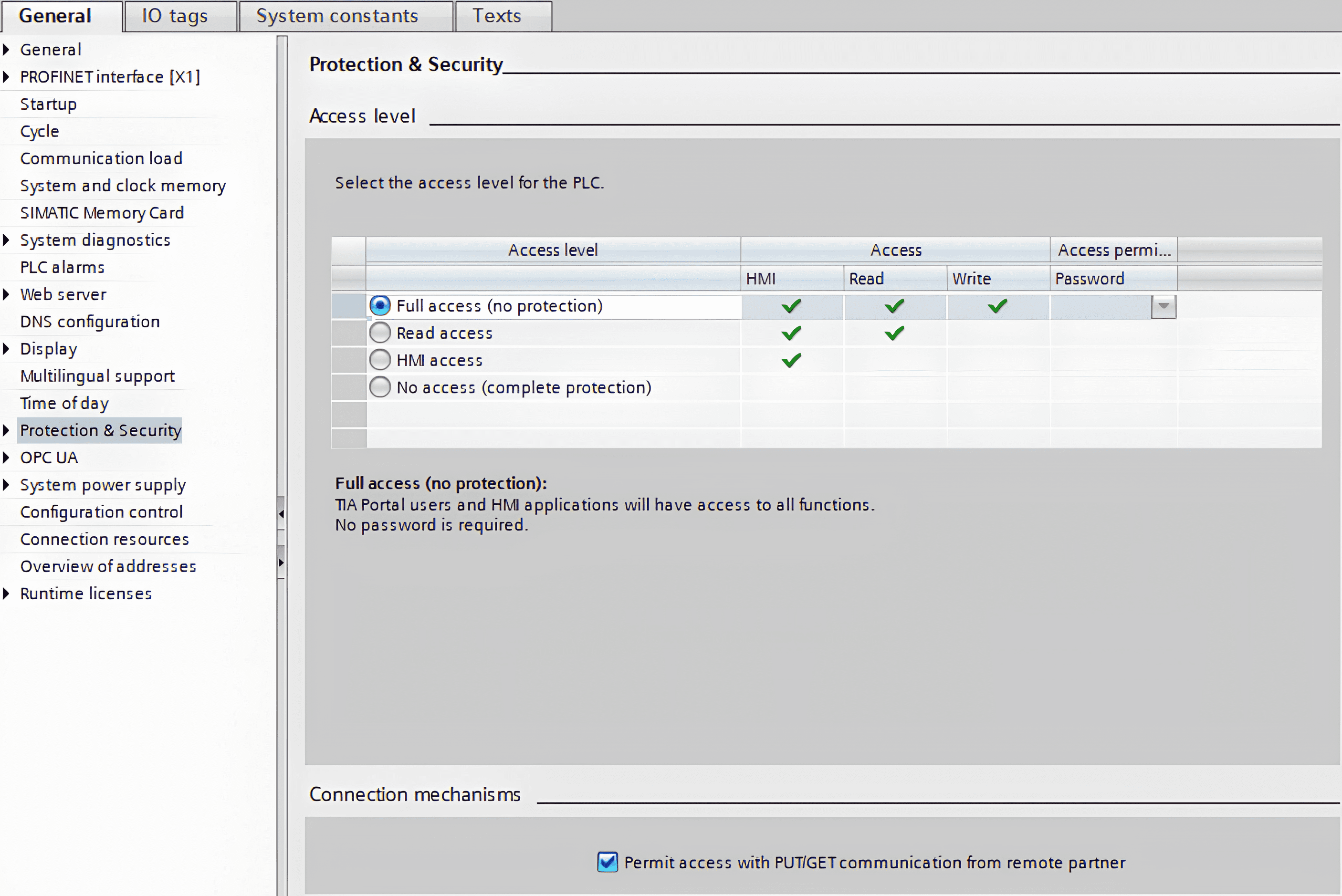

Next, under Device Configuration / Protection & Security, ensure that Full access (no protection) is selected and enable Permit access with PUT/GET.

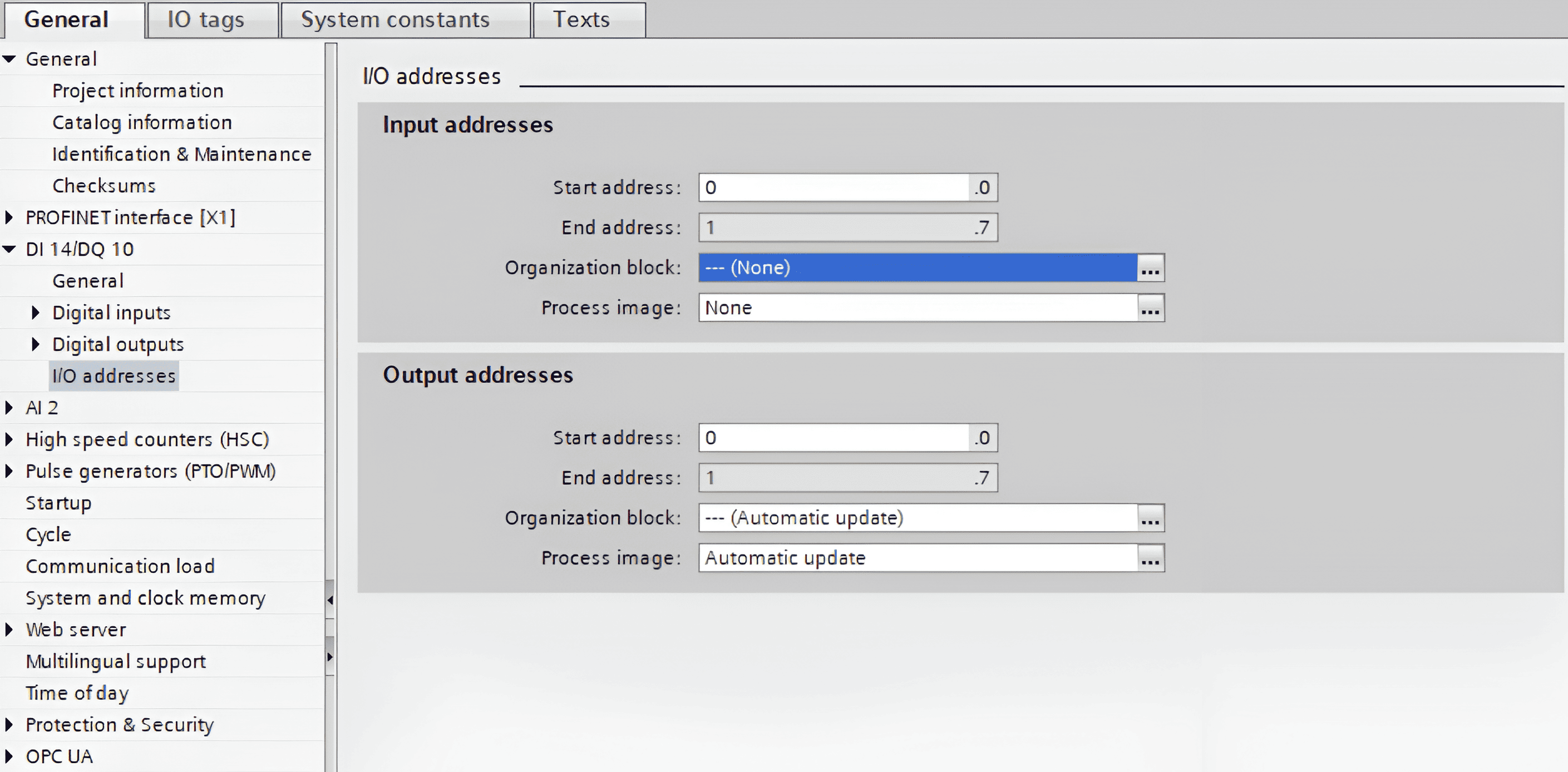

If your PLC has physical inputs, you must prevent the physical inputs from overwriting the values that ProtoTwin Connect will write to the input tags. You can do this either by offsetting the physical input addresses (i.e. setting the Start Address to some large value), or disabling them by setting the Organization Block and Process Image to None.

Note that if you need to read tags from Data Blocks then Optimized Block Access must be disabled under the data block’s properties.

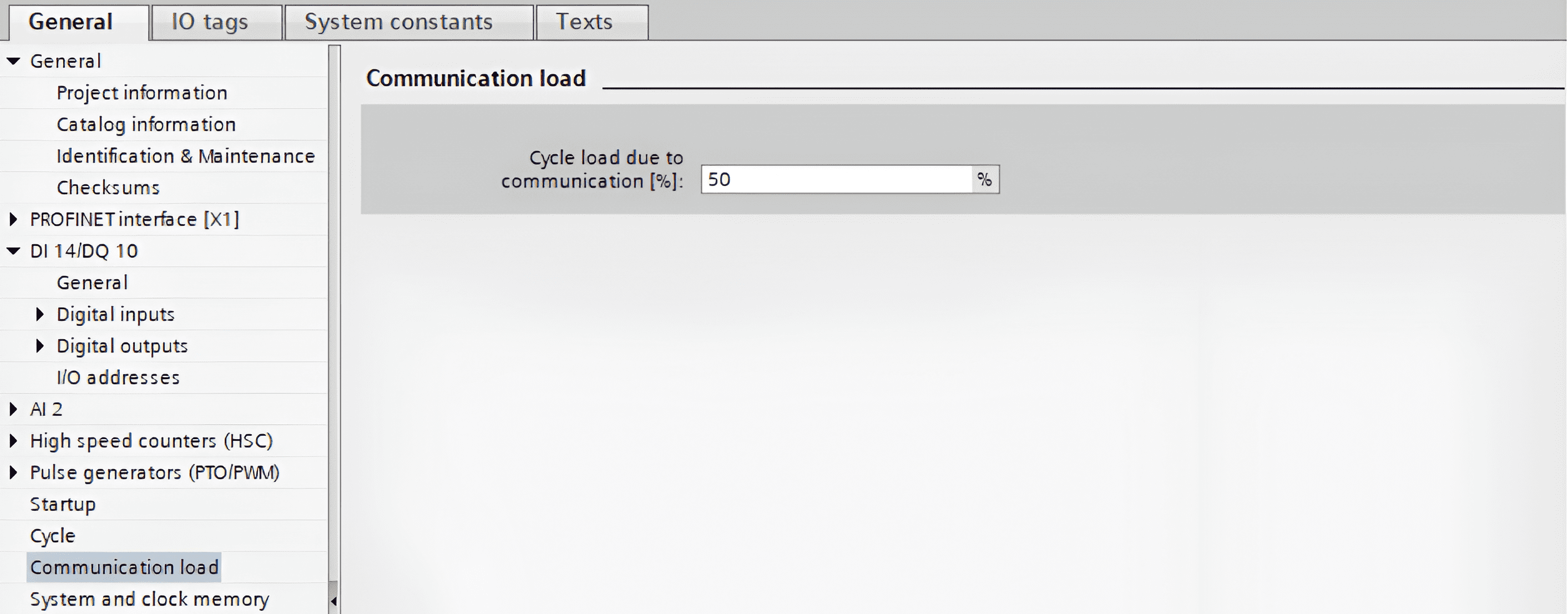

Finally, if you are using a S7-1200, it is recommended to increase the maximum Communication Load to 50% in order to achieve faster communications and lower read/write latency. This will allow the PLC to use up to 50% of its cycle time for performing communications.

For further recommendations on improving communications performance, please refer to the performance section.

Server Configuration

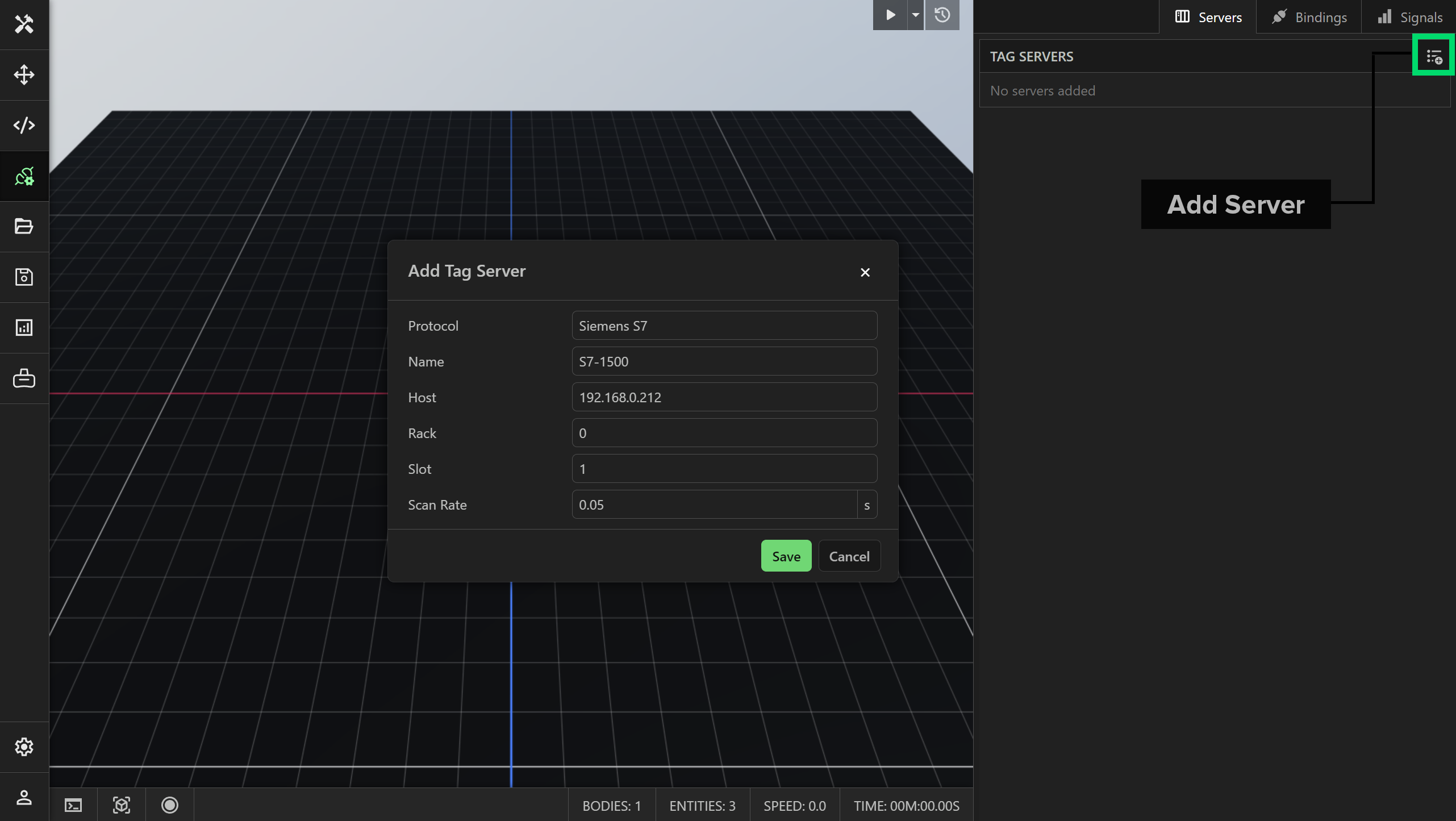

Click the Add Server button in the Servers tab of the IO Browser and configure the server as follows:

- Protocol: Select Siemens S7 from the list.

- Name: Enter a (preferably) unique name, which will be used to identify the server.

- Host: Enter the static IP address of the PLC, as configured in TIA Portal.

- Rack: Enter the rack number, as shown under Device Configuration in TIA Portal.

- Slot: Enter the slot number, as shown under Device Configuration_ in TIA Portal.

- Scan Rate: Enter the desired scan rate, which is the interval (in seconds) at which ProtoTwin Connect will read and write tag values.

Note that the scan rate is the interval at which tags are read and written. The actual rate will depend on the performance of the PLC and networking latency. You can set the scan rate to zero in order to read/write as fast as possible.

Save the configuration to add the tag server.

Connect to Siemens Logo

Soft Comfort Project Setup

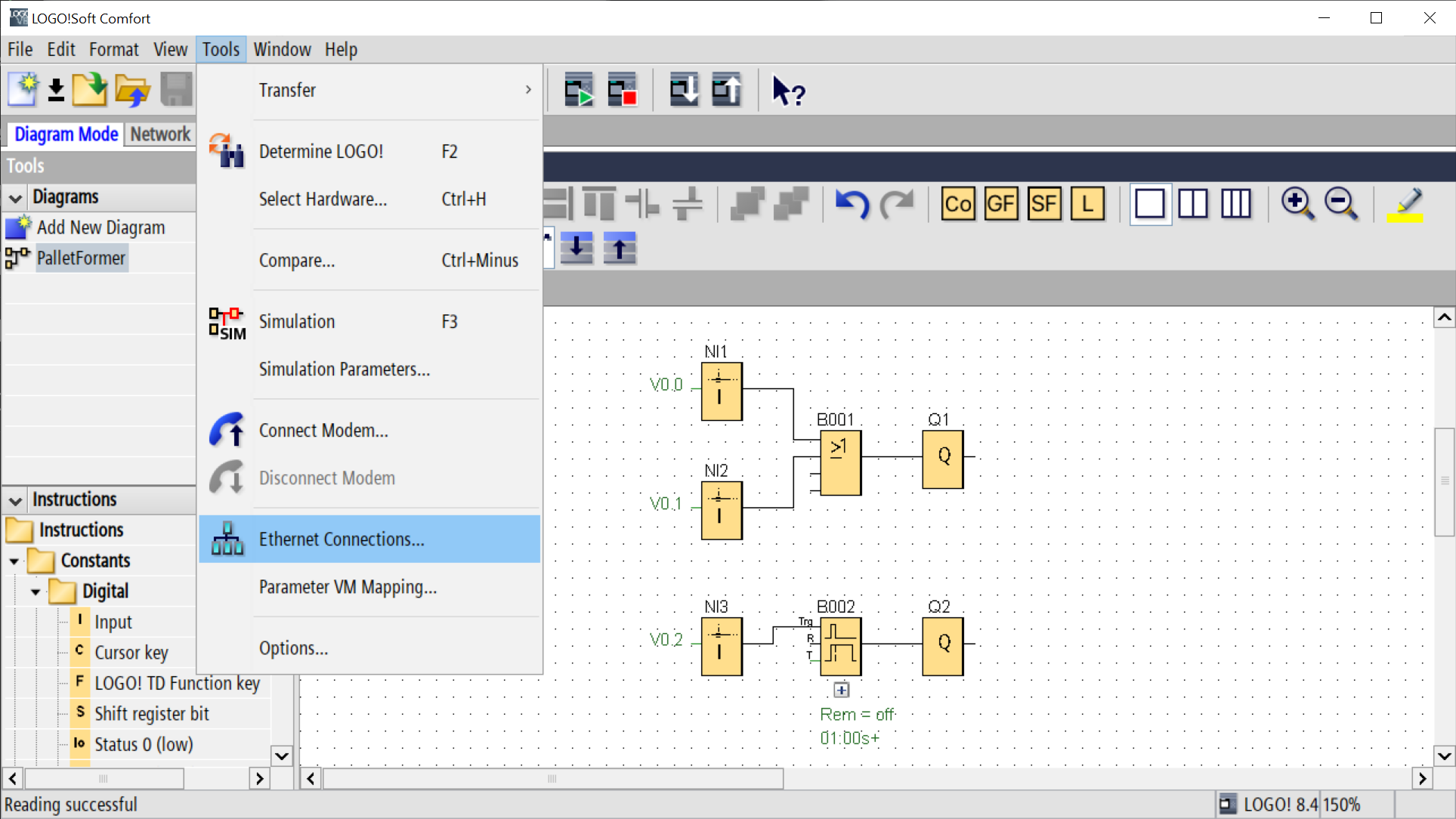

You must configure the Soft Comfort project to allow S7 connections to the PLC. Firstly, select Tools / Ethernet Connections from the toolbar.

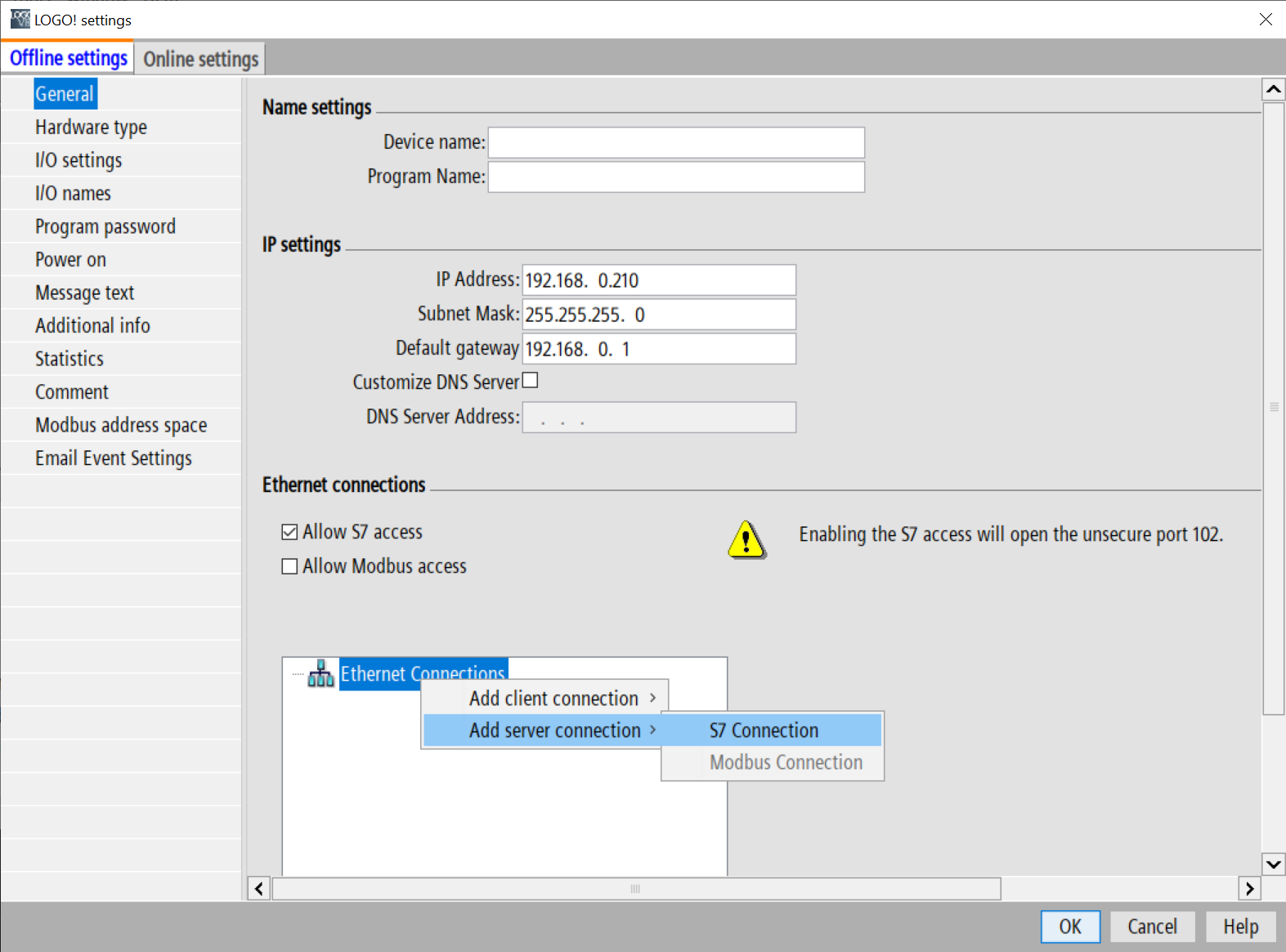

Ensure the option Allow S7 Access is enabled. Right-click on Ethernet Connections and select Add Server Connection / S7 Connection.

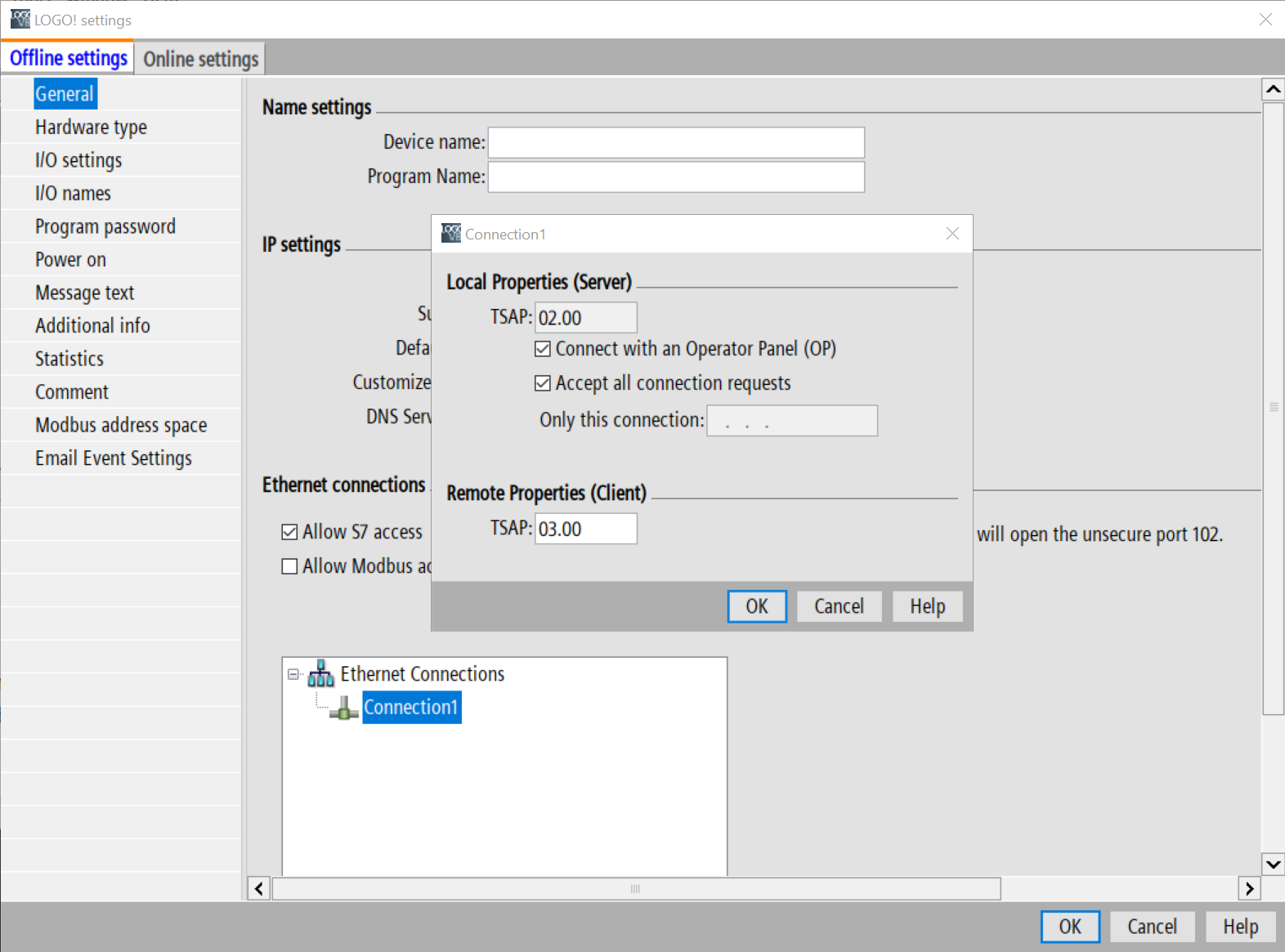

Finally, double click on the created connection to bring up the connection properties. Enable both the Connect with an Operator Panel (OP) and Accept all connection requests options. Set the TSAP for the client to 03.00.

Server Configuration

Add the server in ProtoTwin Connect, following the same procedure as the Siemens 1200/1500 detailed above. Leave the Rack and Slot properties as their default values.

Inputs

Unlike the S7-1200/1500 PLCs, the Logo does not support offsetting/disabling its physical inputs. You must instead use Network Inputs. The address prefix for network inputs is %V. For example, the tag address %V0.2 refers to the third bit of the first byte of the network input area.